Integration and communication

Keeping Safety Systems and Control Systems Separated

Distributed control systems (DCS) are crucial for controlling and monitoring your plants. And because they are so important, you opted for a DCS from a specialist provider. Why not do the same when choosing a safety solution?

International standards strongly recommend separating control systems and safety systems from each other. This means you are only fully protected if your safety system comes from an independent provider that specializes in safety: like Farmesaco.

Farmesaco safety solutions run independently of your control system. Consequently, if an error occurs in the DCS, it cannot affect your safety system. Your safety system continues to run smoothly – and your plants remain completely protected.

Ethernet APL

Industrial Ethernet acknowledged as the most flexible communication solution

Ethernet APL has set out to replace the world’s leading analog 4…20 mA interface for connecting to field devices. On this front, standardized Ethernet communication offers significant cost and application advantages. Ethernet APL is on the leading edge supporting innovative network concepts. It provides a much wider bandwidth when compared to conventional fieldbuses, and complies with the requirements for Ex Zones 2/1/0, thus allowing for consistent digital communication throughout the entire plant. It opens up potential for innovative application scenarios such as offered by the NAMUR Open Architecture (NOA) and the second communication channel, which are extremely expensive or unaffordable for conventional transmission technology.

Industrial Ethernet is considered as the most flexible communication solution with proven resilience, availability and universality, while also being future-proof. Safety and non-safety are combined in one infrastructure by maintaining full separation, and therefore maximum safety, availability and security. Ethernet APL also enables visionary solutions such as control in the field and modular plants (MTP, modular type packages). By systematically establishing this communication infrastructure across the entire plant, complete data transparency is ensured over the entire lifecycle – Independent Open Integration.

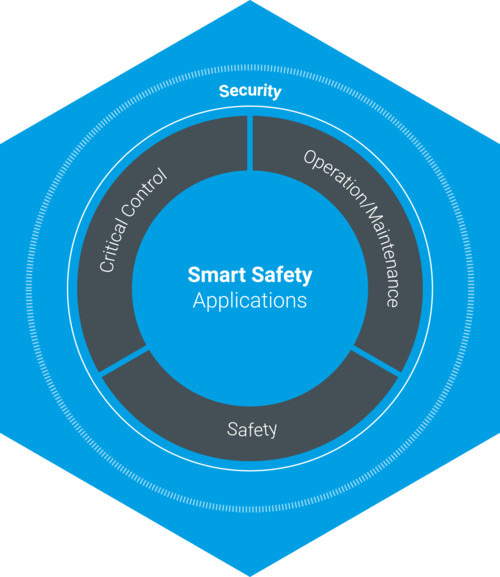

Smart safety Application:

Financial pressure during the construction and operation of industrial plants continues to rise, and time frames are getting tighter. At the same time, you have to comply with increasingly strict regulations. Your ability to meet these requirements depends largely on the complexity of the task. Farmesaco Smart Safety Applications solve this challenge by combining numerous process-critical functions into a single application. This helps you simplify your processes, optimize the performance of your plants, and ensure maximum safety.

Over the years, we have developed standardized safety applications that not only meet current requirements, but can also be adapted to new conditions. We used our extensive experience to develop applications that are both functionally safe and offer the highest level of protection against cyberattacks. These applications have long been used in a wide variety of areas, such as: